product description:

The military standard soft flame-retardant heat-shrinkable tube is composed of radiation cross-linked polyolefin material. It has excellent physical, chemical and electrical properties. The product meets the requirements of the SAE-AMS-DTL-23053/5 military standard. The product is flexible, highly flame-retardant, corrosion-resistant, and Different shrinkage ratio and other characteristics. The main functions are electrical insulation of connectors, rust and corrosion prevention of solder joints, and mechanical protection of wiring harnesses. They are widely used in dual-use fields such as electronics, communications, automobiles, ships, and aircraft manufacturing.

Features:

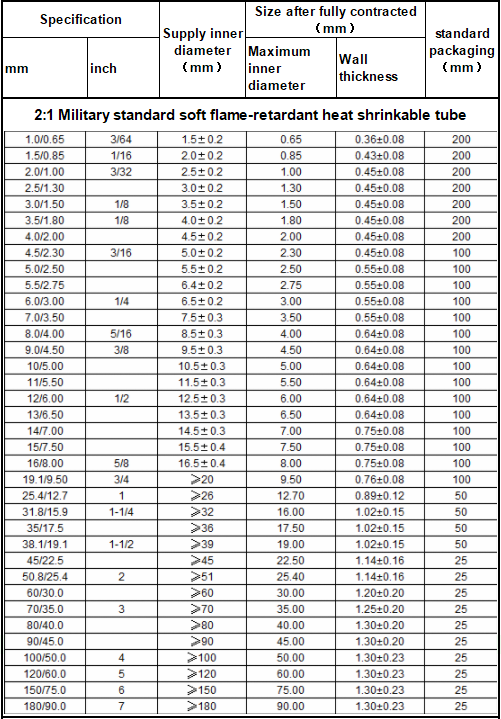

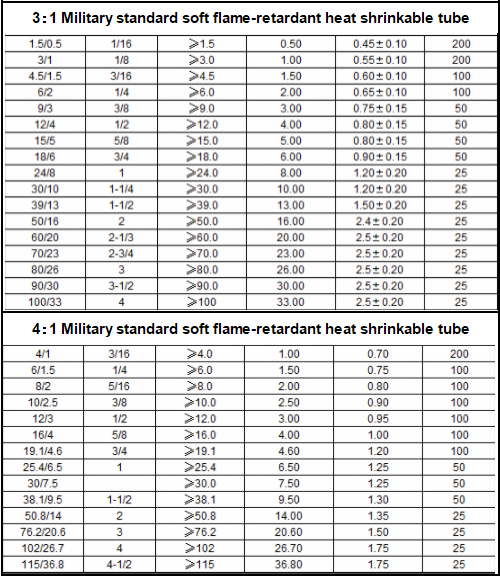

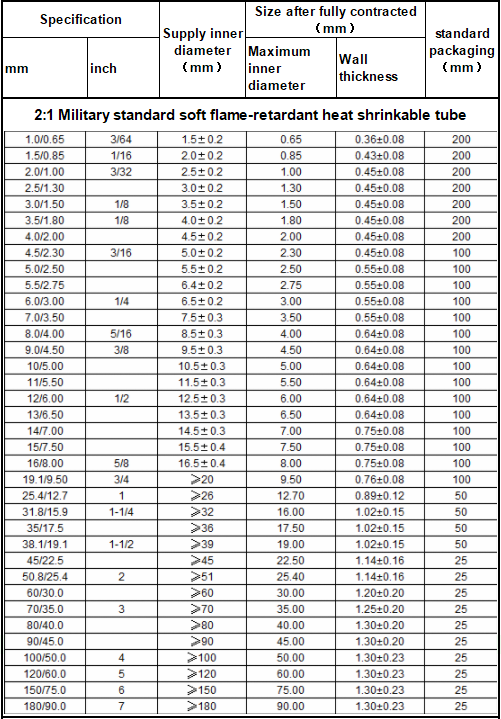

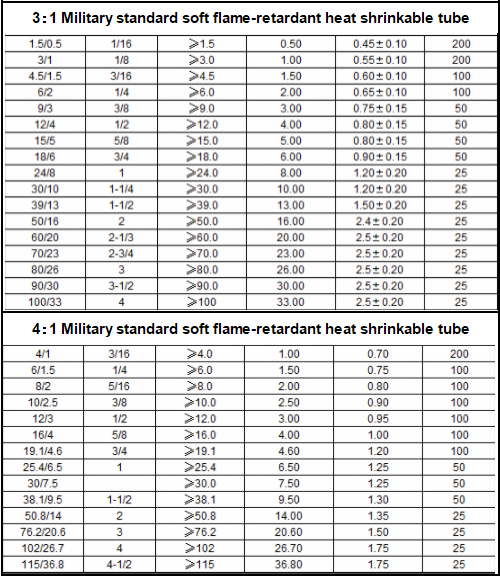

Shrinkage ratio: 2:1; 3:1; 4:1

Soft, highly flame-retardant, resistant to general solvent corrosion and stable performance

Shrinking temperature: 80℃~120℃

Working temperature: -55℃~135℃

Executive standard: SAE-AMS-DTL-2305/5 grade 1-3 UL 224

Environmental protection requirements: RoHS

Standard colors: black, red, yellow, blue, green, white, translucent

Special size and packaging can be customized according to requirements.

中

中

中

中

Product

Product