product description:

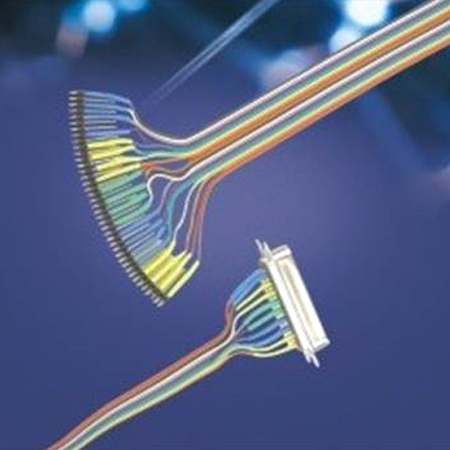

The halogen-free ultra-thin flame-retardant heat-shrinkable tube is composed of radiation cross-linked polyolefin material, which has the characteristics of ultra-thin wall thickness, high flexibility, rapid shrinkage at low temperature, and flame retardancy. It is suitable for specific occasions that require low shrinkage temperature, fast shrinkage speed and rapid shrinkage in a narrow space, which can avoid temperature damage to temperature-sensitive components.

Features:

Shrinkage ratio: 2:1

Shrinking temperature: 70℃~120℃

Working temperature: -55℃~125℃

Withstand voltage rating: 300V

Executive standard: UL 224

Environmental standards: RoHS

Standard colors: black, white, red, yellow, green, blue

| Specification | Supply inner diameter

(mm) | Size after fully contracted(mm) | Standard length

(mm) |

| the inside diameter of | Wall thickness |

| Φ1.0 | 1.4±0.20 | ≤0.65 | 0.20±0.10 | 200 |

| Φ1.5 | 1.9±0.20 | ≤0.85 | 0.20±0.10 | 200 |

| Φ2.0 | 2.4±0.20 | ≤1.00 | 0.22±0.10 | 200 |

| Φ2.5 | 2.9±0.20 | ≤1.30 | 0.25±0.10 | 200 |

| Φ3.0 | 3.4±0.20 | ≤1.50 | 0.28±0.10 | 200 |

| Φ3.5 | 4.0±0.20 | ≤1.80 | 0.28±0.10 | 200 |

| Φ4.0 | 4.5±0.20 | ≤2.00 | 0.30±0.10 | 200 |

| Φ4.5 | 5.0±0.20 | ≤2.25 | 0.30±0.10 | 100 |

| Φ5.0 | 5.5±0.20 | ≤2.50 | 0.30±0.10 | 100 |

| Φ5.5 | 6.0±0.20 | ≤3.00 | 0.30±0.10 | 100 |

| Φ6.0 | 6.5±0.20 | ≤3.00 | 0.32±0.10 | 100 |

| Φ7.0 | 7.5±0.30 | ≤3.50 | 0.32±0.10 | 100 |

| Φ8.0 | 8.5±0.30 | ≤4.00 | 0.35±0.10 | 100 |

| Φ9.0 | 9.5±0.30 | ≤4.50 | 0.35±0.10 | 100 |

| Φ10 | 10.5±0.30 | ≤5.00 | 0.35±0.10 | 100 |

| Φ11 | 11.5±0.30 | ≤5.50 | 0.40±0.10 | 100 |

| Φ12 | 12.5±0.30 | ≤6.00 | 0.40±0.10 | 100 |

| Φ13 | 13.5±0.30 | ≤6.50 | 0.40±0.10 | 100 |

| Φ14 | 14.5±0.40 | ≤7.00 | 0.40±0.10 | 100 |

| Φ15 | 15.5±0.40 | ≤7.50 | 0.40±0.10 | 100 |

| Φ16 | 16.5±0.40 | ≤8.00 | 0.40±0.10 | 100 |

| Φ17 | 17.5±0.40 | ≤8.50 | 0.40±0.10 | 100 |

| Φ18 | 18.5±0.40 | ≤9.00 | 0.42±0.10 | 100 |

| Φ20 | 20.5±0.50 | ≤10.0 | 0.45±0.10 | 100 |

| Φ22 | 22.5±0.50 | ≤11.0 | 0.45±0.10 | 100 |

| Φ25 | 25.5±0.50 | ≤12.5 | 0.45±0.10 | 50 |

| Φ28 | 28.5±0.50 | ≤14.0 | 0.45±0.10 | 50 |

Special size and packaging can be customized according to requirements.

中

中

中

中

Product

Product