product description:

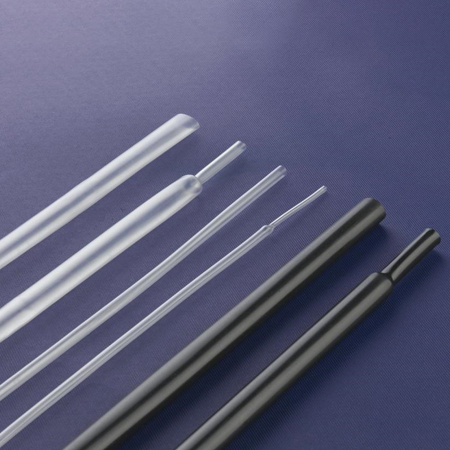

The halogen-free non-flame retardant heat-shrinkable tube is made of radiation cross-linked polyolefin material, general-purpose non-flame-retardant heat-shrinkable tube, with bright surface, halogen-free, soft, low smoke and non-toxic, good insulation performance, low shrinkage temperature, physical and chemical electrical Excellent performance, widely used in automobiles, electronic appliances, decoration and lighting, communications, agricultural and household bending pipe mechanical protection, insulation and mechanical protection required but not flame retardant occasions.

Features:

Shrinkage ratio: 2:1

Shrinking temperature: 70℃~105℃

Working temperature: -55℃~105℃

Executive standard: UL 224

Withstand voltage rating: 600V

Environmental standards: RoHS

Standard color: transparent, bright black (other colors can be produced on request)

| Specification | Supply inner diameter

(mm) | After full contraction(mm) | Standard packaging

(M/plate) |

| Maximum inner diameter | Wall thickness |

| Φ0.5/0.35 | 0.70±0.20 | 0.35 | 0.33±0.10 | 400 |

| Φ0.6/0.40 | 0.90±0.20 | 0.40 | 0.33±0.10 | 200 |

| Φ0.8/0.50 | 1.10±0.20 | 0.50 | 0.33±0.10 | 200 |

| Φ1.0/0.65 | 1.50±0.20 | 0.65 | 0.36±0.10 | 200 |

| Φ1.5/0.85 | 2.00±0.20 | 0.85 | 0.36±0.10 | 200 |

| Φ2.0/1.00 | 2.50±0.20 | 1.00 | 0.40±0.10 | 200 |

| Φ2.5/1.30 | 3.00±0.20 | 1.30 | 0.42±0.10 | 200 |

| Φ3.0/1.50 | 3.50±0.20 | 1.50 | 0.44+0.10 | 200 |

| Φ3.5/1.80 | 4.00±0.20 | 1.80 | 0.44±0.10 | 200 |

| Φ4.0/2.00 | 4.50±0.30 | 2.00 | 0.44±0.10 | 200 |

| Φ4.5/2.30 | 5.00±0.20 | 2.30 | 0.44±0.10 | 100 |

| Φ5.0/2.50 | 5.50±0.20 | 2.50 | 0.52±0.10 | 100 |

| Φ5.5/2.75 | 6.00±0.20 | 2.75 | 0.52±0.10 | 100 |

| Φ6.0/3.00 | 6.50±0.30 | 3.00 | 0.54±0.10 | 100 |

| Φ7.0/3.50 | 7.50±0.30 | 3.50 | 0.54±0.10 | 100 |

| Φ8.0/4.00 | 8.50±0.30 | 4.00 | 0.54±0.10 | 100 |

| Φ9.0/4.50 | 9.50±0.30 | 4.50 | 0.54±0.10 | 100 |

| Φ10/5.00 | 10.50±0.30 | 5.00 | 0.54+0.10 | 100 |

| Φ11/5.50 | 11.50±0.30 | 5.50 | 0.56±0.10 | 100 |

| Φ12/6.00 | 12.50±0.30 | 6.00 | 0.56±0.10 | 100 |

| Φ13/6.50 | 13.50±0.30 | 6.50 | 0.62±0.10 | 100 |

| Φ14/7.00 | 14.50±0.30 | 7.00 | 0.70±0.10 | 100 |

| Φ15/7.50 | 15.50±0.40 | 7.50 | 0.70±0.10 | 100 |

| Φ16/8.00 | 16.50±0.40 | 8.00 | 0.70±0.10 | 100 |

| Φ18/9.00 | 19.00±0.50 | 9.00 | 0.70±0.10 | 100 |

| Φ20/10.0 | 22.00±0.50 | 10.00 | 0.80±0.15 | 100 |

| Φ22/11.0 | 24.00±0.50 | 11.00 | 0.80±0.15 | 100 |

| Φ25/12.5 | 26.00±0.50 | 12.50 | 0.90±0.15 | 50 |

| Φ28/14.0 | 29.00±0.50 | 14.00 | 0.90±0.15 | 50 |

| Φ30/15.0 | 31.50±1.00 | 15.00 | 1.00±0.15 | 50 |

| Φ35/17.5 | 36.50±1.00 | 17.50 | 1.00±0.15 | 50 |

| Φ40/20.0 | 41.50±1.00 | 20.00 | 1.00±0.15 | 50 |

| Φ50/25.0 | ≥50.0 | 25.00 | 1.10±0.15 | 25 |

| Φ60/30.0 | ≥60.0 | 30.00 | 1.20±0.15 | 25 |

| Φ70/35.0 | ≥70.0 | 35.00 | 1.30±0.15 | 25 |

| Φ80/40.0 | ≥80.0 | 40.00 | 1.30±0.20 | 25 |

| Φ90/45.0 | ≥90.0 | 45.00 | 1.30±0.20 | 25 |

| Φ100/50.0 | ≥100 | 50.00 | 1.30±0.20 | 25 |

| Φ120/60.0 | ≥120 | 60.00 | 1.30±0.20 | 25 |

| Φ150/75.0 | ≥150 | 75.00 | 1.30±0.20 | 25 |

| Φ180/90.0 | ≥180 | 90.00 | 1.30±0.20 | 25 |

| Φ210/105 | ≥210 | 105.00 | 1.30±0.30 | 25 |

Special size and packaging can be customized according to requirements.

中

中

中

中

Product

Product