product description:

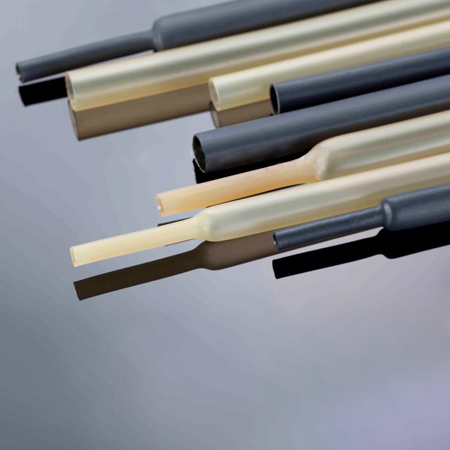

Semi-rigid flame-retardant double-wall heat-shrinkable tube is made of polyolefin and polyamide hot melt adhesive melted and co-extruded. The outer layer is semi-hard polyolefin, which has high hardness, wear resistance and strength, high shrinkage ratio, good adhesion and sealing performance of the inner layer, and is widely used in automobile wiring harness, wire and cable branch, metal pipeline, wire and cable repair , Submersible pump wiring and other occasions requiring insulation and sealing.

Features:

Working temperature: -45℃~+125℃

Full shrinkage temperature: 135℃

Shrinkage ratio: 5:1

Environmental standards: RoHS

Standard color: black, transparent (non-flame retardant)

| Specification | Supply inner diameter ( mm) | Size after fully contracted (mm) | standard packaging (M/root) |

| the inside diameter of | Total wall thickness | Adhesive layer thickness |

| YEVA-BK-6.0 / 1.27 | ≥6.0 | ≤1.27 | 1.30±0.15 | 0.50±0.10 | 1.22 |

| YEVA-BK-8.0 / 1.65 | ≥8.0 | ≤1.65 | 1.52±0.15 | 0.70±0.10 | 1.22 |

| YEVA-BK-12.0 / 2.41 | ≥12.0 | ≤2.41 | 1.91±0.15 | 0.90±0.10 | 1.22 |

| YEVA-BK-18.0 / 4.45 | ≥18.0 | ≤4.45 | 2.41±0.15 | 1.20±0.10 | 1.22 |

中

中

中

中

Product

Product