product description:

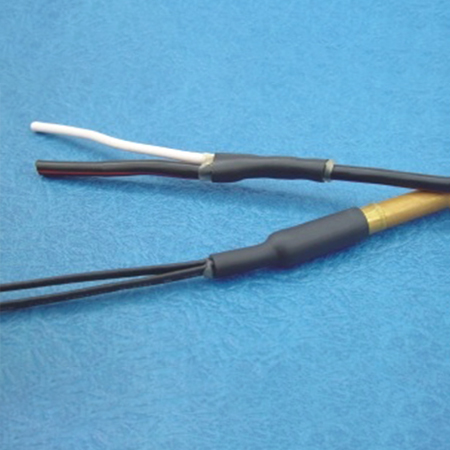

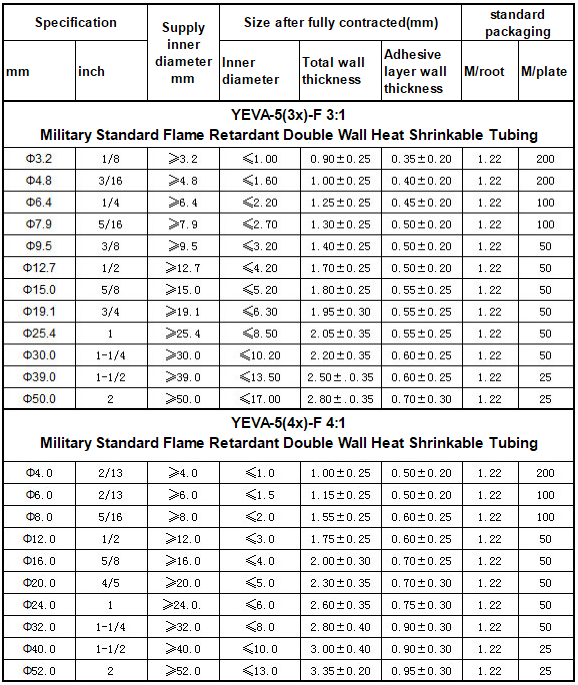

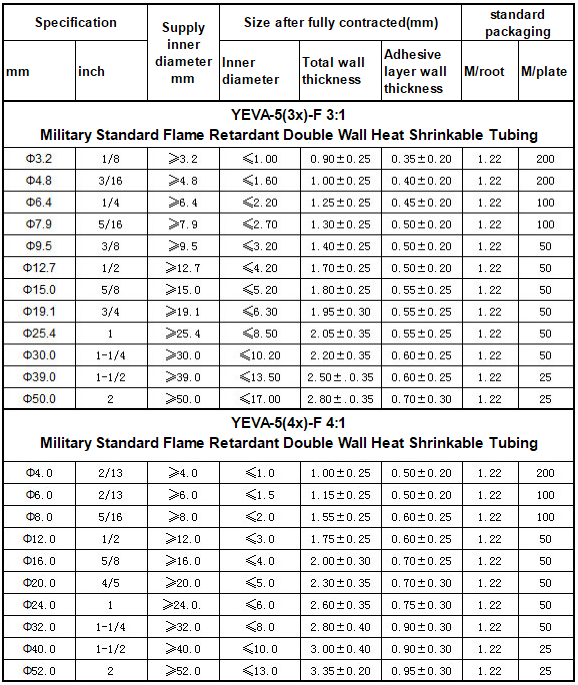

Military standard flame-retardant 3:1, 4:1 double-wall pipes are made of polyolefin and hot melt adhesive using melt co-extrusion technology. The outer layer is polyolefin insulating and flame retardant material, and the inner layer of hot melt adhesive can buffer mechanical stress. And sealing performance. The main function is to seal waterproof, anti-corrosion, anti-leakage, multi-strand wire harness and insulation. It is widely used for waterproof and moisture-proof of various wire harnesses, automotive wires, marine wires and cables and metal pipes, and insulation and sealing protection in moisture-proof and anti-corrosion occasions.

Features:

Shrinking temperature: 70℃~125℃

Working temperature: -55℃~+135℃

Executive standard: UL 224 125℃ vw-1 600V

Environmental standards: RoHS

Standard color: black, transparent (non-flame retardant)

Special specifications and cut pipes can be produced on request.

中

中

中

中

Product

Product