product description:

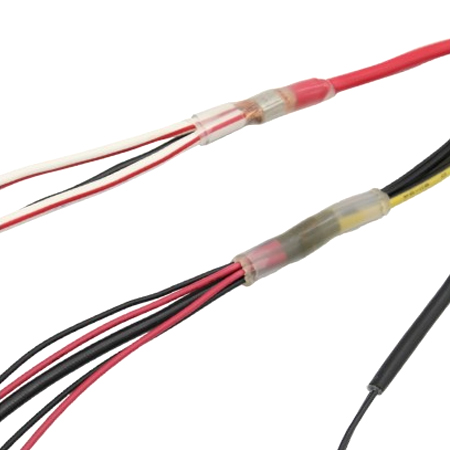

4:1 Double-wall heat-shrinkable tubing for automobile wiring harness is composed of polyolefin and hot-melt adhesive. The outer layer is made of polyolefin insulating and flame-retardant material, and the inner layer of hot-melt adhesive can buffer mechanical stress and sealing performance. The main function is sealing, waterproof, anti-corrosion, anti-leakage, multi-strand wiring harness and insulation. It is widely used in the wire connection of various electronic equipment, home wiring harness, automobile wiring harness, wire and cable branching, submersible pump wiring and other occasions that require insulation and sealing.

Features:

Shrinking temperature: 70℃~125℃

Working temperature: -45℃~125℃

Shrinkage ratio: 4:1

Executive standard: UL 224 125℃ vw-1 600V

Environmental standards: RoHS

Standard color: black (other colors can be customized)

| Specification | Supply inner diameter

(mm) | Size after fully contracted(mm) | standard packaging |

| mm | inch | the inside diameter of | Total wall thickness | Adhesive layer thickness | Rice/root; rice/pan |

| Φ4.0 | 5/32 | ≥4.0 | ≤1.00 | 1.20±0.20 | 0.50±0.20 | 1.22 | 200 |

| Φ6.0 | 1/4 | ≥6.0 | ≤1.25 | 1.40±0.20 | 0.55±0.20 | 1.22 | 100 |

| Φ8.0 | 5/16 | ≥8.0 | ≤1.65 | 1.70±0.20 | 0.75±0.20 | 1.22 | 100 |

| Φ10.0 | 2/5 | ≥10.0 | ≤2.10 | 1.90±0.20 | 0.95±0.20 | 1.22 | 1.22 |

| Φ12.0 | 1/2 | ≥12.0 | ≤2.40 | 2.10±0.20 | 1.02±0.20 | 1.22 | 1.22 |

| Φ18.0 | 3/4 | ≥18.0 | ≤4.40 | 2.60±0.20 | 1.30±0.20 | 1.22 | 1.22 |

Special specifications, lengths, cutting pipes can be produced according to requirements

中

中

中

中

Product

Product