product description:

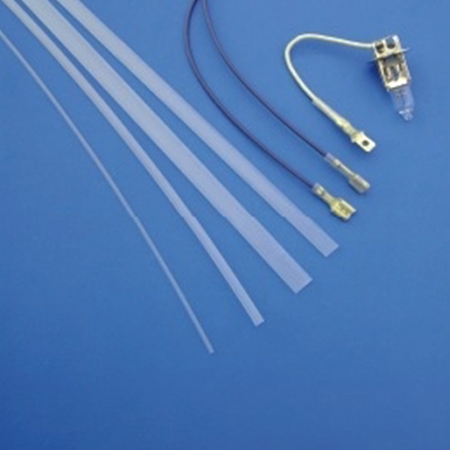

The product is made of radiation cross-linked modified polyvinylidene fluoride (PVDF). It has the characteristics of softness, thin wall, high temperature resistance, chemical corrosion resistance, flame retardant and so on. It is widely used in the protection of solder joints, terminals and connection lines that are invaded by high temperature, industrial solvents and chemical reagents.

Features:

Shrinkage ratio: 2:1

Shrinking temperature: 100℃~150℃

Working temperature: -55℃~150℃

Executive standard: UL VW-1

Environmental protection standard: ROHS

Standard color: transparent, black

| Specification | Supply inner diameter

(mm) | Size after fully contracted(mm) | Tube type | Standard length

(M/plate) |

| mm | inch | the inside diameter of | Wall thickness |

| 1.2 | 3/64 | ≥1.2 | ≤0.60 | 0.25±0.05 | Round | 200 |

| 1.6 | 1/16 | ≥1.6 | ≤0.80 | 0.25±0.05 | Round | 200 |

| 2.4 | 3/32 | ≥2.4 | ≤1.20 | 0.25±0.05 | Round | 200 |

| 3.2 | 1/8 | ≥3.2 | ≤1.60 | 0.25±0.05 | Round | 200 |

| 4.8 | 3/16 | ≥4.8 | ≤2.40 | 0.25±0.05 | Round | 100 |

| 6.4 | 1/4 | ≥6.4 | ≤3.20 | 0.25±0.05 | Round | 100 |

| 9.5 | 3/8 | ≥9.5 | ≤4.80 | 0.30±0.05 | Flat | 50 |

| 12.7 | 1/2 | ≥12.7 | ≤6.40 | 0.30±0.05 | Flat | 50 |

| 19.1 | 3/4 | ≥19.1 | ≤9.50 | 0.45±0.05 | Flat | 50 |

| 25.4 | 1 | ≥25.4 | ≤12.70 | 0.45±0.05 | Flat | 50 |

| 38.1 | 1-1/2 | ≥38.1 | ≤19.10 | 0.50±0.05 | Flat | 50 |

中

中

中

中

Product

Product