product description:

YEVA-AMS---Military-standard heat-shrinkable marking tube is composed of radiation cross-linked polyolefin material, which meets the requirements of high temperature and high temperature organic solvent use environment, and has the characteristics of anti-ultraviolet, soft and flame retardant. The main function is to identify the cable interface of the signal and power system. It is widely used in fields such as communications, precision instruments, automobiles, ships, spacecraft, airplanes, and nuclear power islands.

Features:

Executive standard: Class 1 in military AMS-DTL-23053/6

Color code durability standard: SAE AS 81531 and MIL-STD-202F/215J

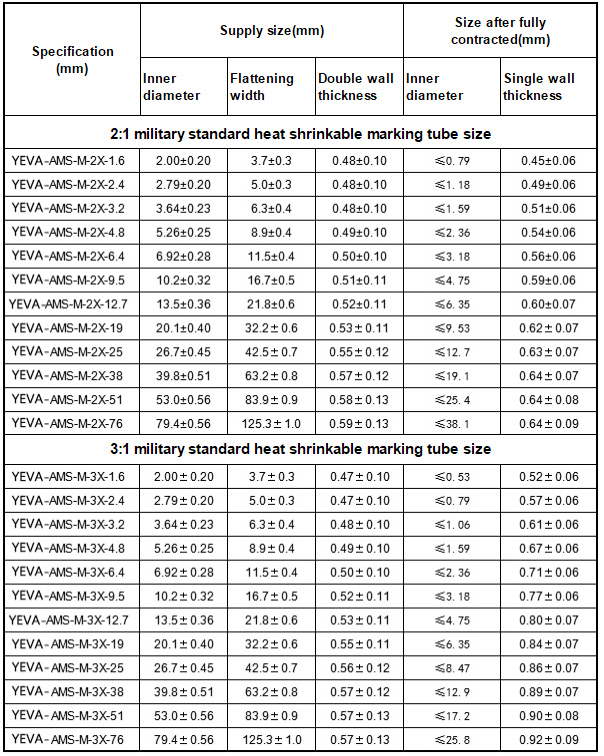

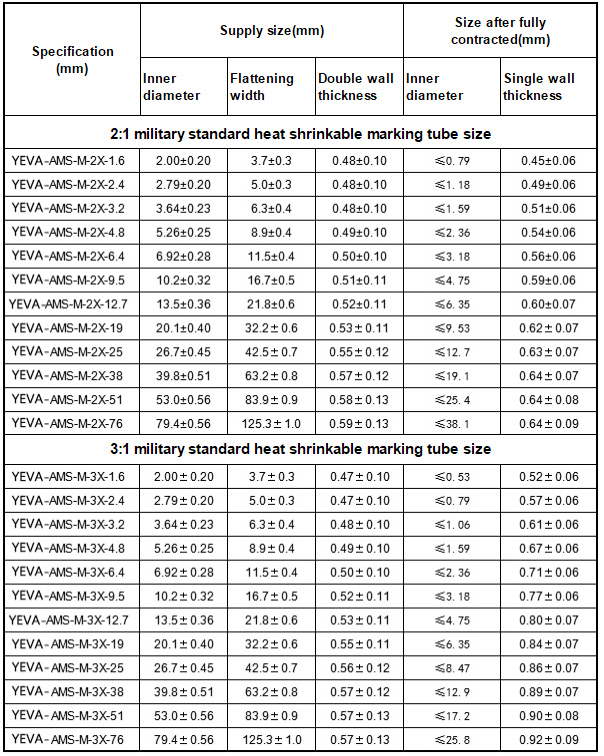

Heat shrinkage ratio: 2:1 and 3:1

Shrinking temperature: 120℃~155℃

Working temperature: -55℃~135℃

Environmental standards: RoHs

Standard color: 10 standard colors such as yellow and white are available

中

中

中

中

Product

Product