product description:

The busbar heat-shrinkable tube is composed of radiation cross-linked polyolefin material, which has the characteristics of halogen-free flame retardant, electric tracking resistance, UV resistance, and good physical and chemical electrical properties. The main function is the electrical insulation of the connectors, mechanical protection, and reduction of phase spacing. , It is widely used in the insulation protection of power busbars.

Features

Shrinkage ratio: 2:1

Working temperature: -55℃~+110℃

Shrinking temperature: 70℃~120℃

Suitable for 10~35kV voltage level

Environmental standards: RoHS

Color: iron red, yellow, green

The cutting length can be provided according to customer requirements

中

中

中

中

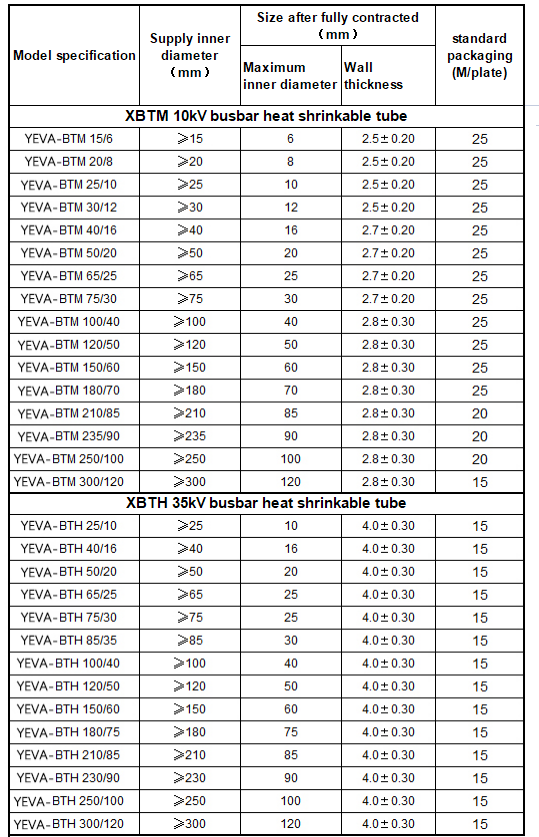

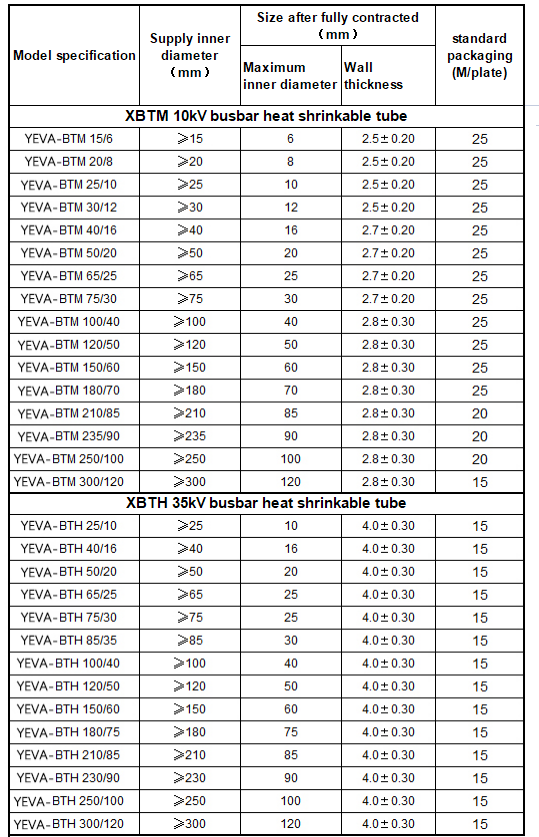

Product

Product