HB1512 sealing waterstop is strong and sticky, providing a stable and reliable bonding effect.

product information

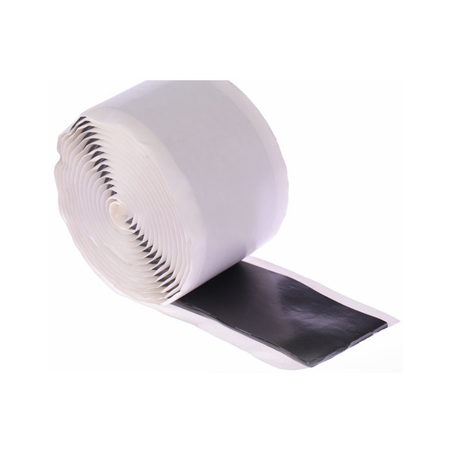

Specification: 3.0mm (thickness) × 50mm (width) × 3m (length), can be customized

Colour: Black

Appearance: soft tape or roll

Working conditions: -40℃~90℃

Packing specification: 36 rolls/carton

Product Features

1. It has good strength and adhesiveness, providing a stable and reliable bonding effect.

2. There is no negative impact on the quality and performance of the product under high temperature in a short time, and it has good adhesion and aging resistance.

Scope of application

1. The communication cable terminal and connector (box) are sealed to prevent water and moisture. They are used to clean the surface of metal and non-metal materials to protect, seal, adhere and prevent vibration.

2. Bonding, waterproofing and sealing between steel plates in the manufacturing process of large-scale refrigerators.

3. Bonding, sealing, damping and noise reduction between riveted steel plates in the assembly process of various boxes.

Instructions for use

Clean the surface of the bonded object to ensure that there is no dust, oil, etc., stretch to 1/2-3/4 of the original width, 1/2 overlap, and press hard at the end to ensure good bonding.

中

中

中

中

Product

Product