HB1103 waterproof sealant can be used for sealing and waterproofing of heat-shrinkable and cold-shrinkable power cable accessory terminals and joints. It can also be used for bonding and sealing the joints of electrical equipment and heat shrinkable plastic sleeves.

product information

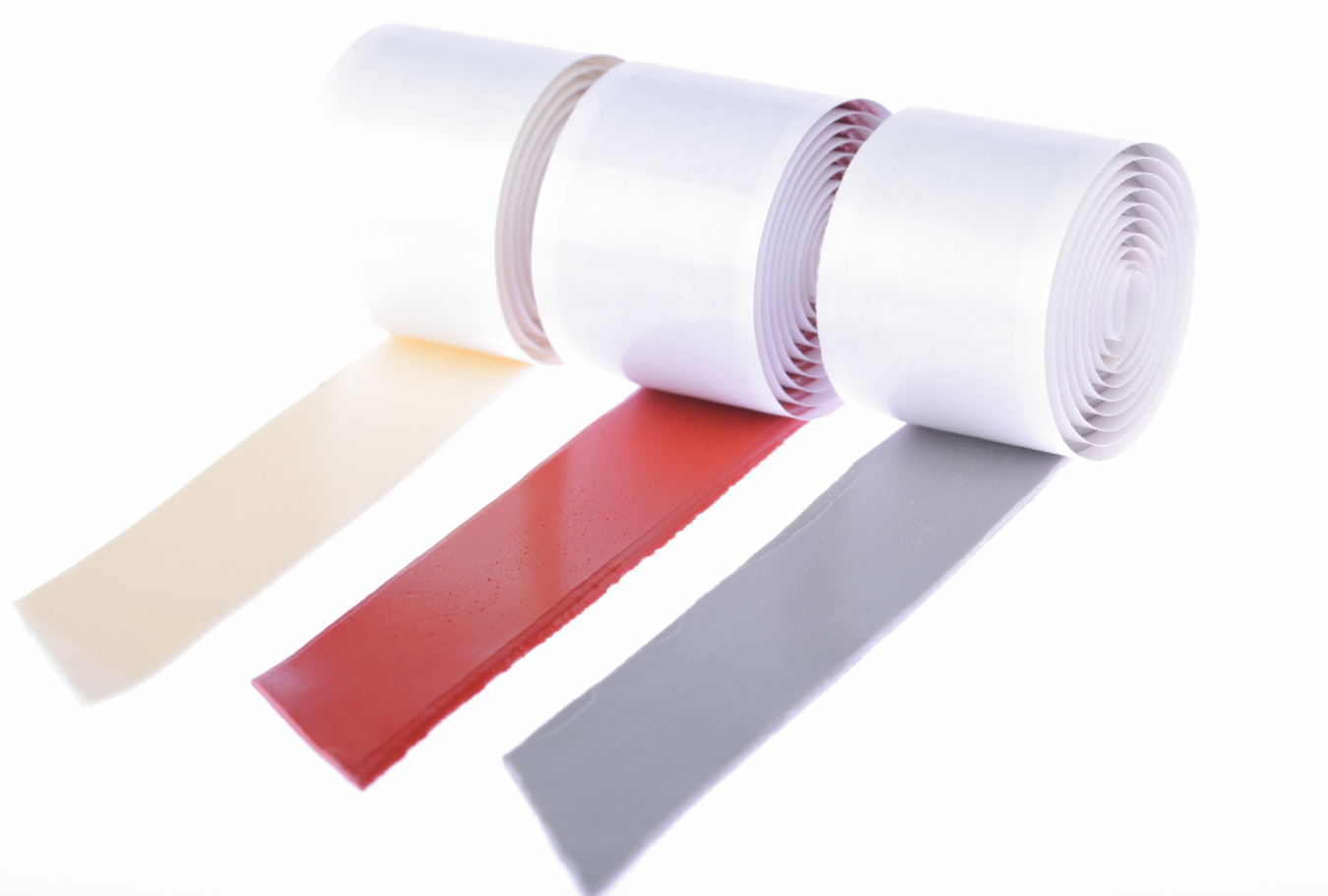

Specification: 2.0 mm (thickness) × 30 mm (width) × 360mm (length) or 50-200g/roll, can be customized

Color: red, gray, black, white

Appearance: soft self-melting tape or roll

Working conditions: -40℃~90℃

Packing specification: 15KG/carton

Product Features

1. High bonding strength, excellent sealing and water resistance.

2. Excellent electrical performance. Weather resistance and aging resistance.

3. Good elasticity, excellent conformability, extremely high bending resistance, and low-temperature mobile operation.

4. Easy to use and flexible.

Scope of application

1. The bonding and sealing of cold and heat shrinkable outdoor pipe joints of power cable accessories, as well as the bonding of umbrella skirts and the sealing and bonding parts of high-pressure heads.

2. Bonding and sealing of electrical equipment connectors (including lead outlets) and cable interfaces or lead outlets of electrical control equipment in the fields of aerospace, aviation, shipbuilding and rail transit.

Instructions for use

Clean the area where the glue is going to be wrapped, and there should be no dust, oil, etc. Stretch the tape to 1/2 of the original width, overlap the tape with 1/2 overlap, and wrap it in multiple layers so that the thickness of the waterproof glue is not less than 2mm and the width is about 5cm. The closing part is compacted by hand to check whether it is bonded. good.

中

中

中

中

Product

Product