product description:

Rubber co-extrusion type mid-wall heat shrinkable tube, the outer layer of semi-hard polyolefin and inner layer of hot melt adhesive are directly compounded by extrusion and co-extrusion. It has good physical and insulation, sealing, moisture resistance, impact resistance and abrasion resistance. . .Mainly used for sealing and insulation protection of cable terminals or intermediate connections, as well as other working environments that require anti-corrosion, moisture-proof, and mechanical protection.

Features

Shrinkage ratio: 3:1

Good UV resistance

Working temperature: ﹣45℃~110℃

Shrinking temperature: 70℃~125℃

Environmental standards: RoHs

Standard color: black (other colors can be customized)

中

中

中

中

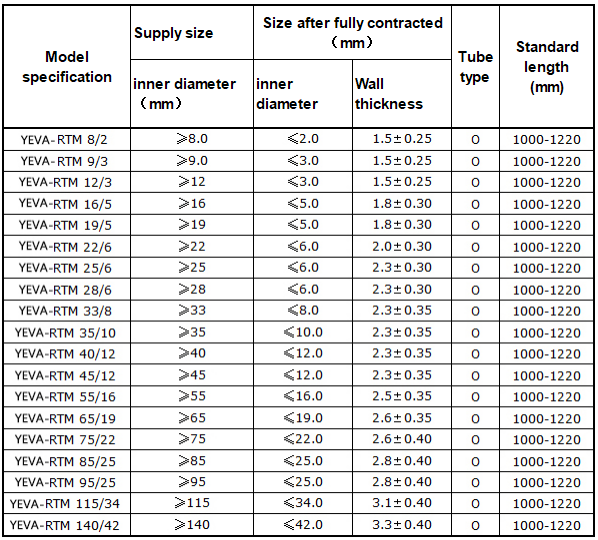

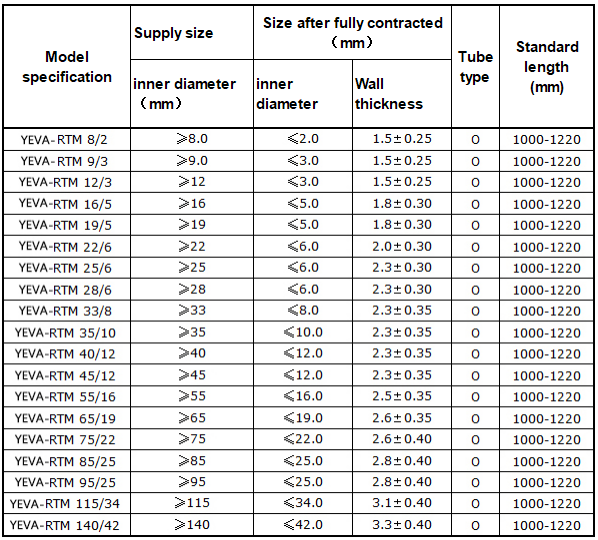

Product

Product