product description:

The anticorrosive heat-shrinkable sleeve consists of a three-layer structure composed of a radiation cross-linked polyolefin outer layer, a two-component liquid epoxy primer and an inner layer of hot melt adhesive. The main function is to seal, waterproof, anti-corrosion, and protect exposed metal parts. Mainly used in oil or natural gas long-distance pipelines, anti-corrosion at the welded joints of thermal insulation pipelines, pipeline flange connections, insulating flanges and sealing and anti-corrosion of clamp parts.

Features:

Simple and quick installation, fast shrinkage, easy construction

UV resistant, long service life, good waterproof and sealing performance

The matching epoxy primer can be applied after preheating to 40~60℃, which can be applied to dry film or wet film construction

Strong bonding ability, compatible with various pipe surface materials, such as steel pipe, thermal insulation jacket, epoxy coating, and PE, etc.

Executive standard: sy/t 0413-2002; GB/T 23257

中

中

中

中

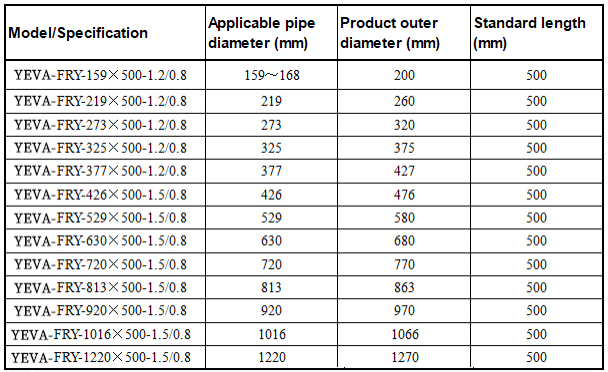

Product

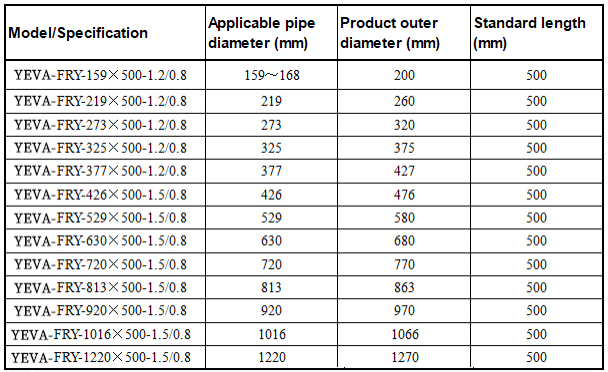

Product